Robuschi Blowers

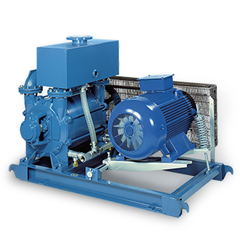

Robuschi blowers are a type of positive displacement blower that are used to move air or gas in various industrial applications. Robuschi is a leading manufacturer of blowers and has been producing high-quality equipment for over 75 years.

Robuschi blowers are known for their reliability, efficiency, and durability. They are commonly used in applications such as wastewater treatment, pneumatic conveying, and chemical processing.

- Rotary lobe blowers with pressure to 1,000 mbar (g), vacuum to 100 mbar (a) & air flow to 25,000 m³/h

- Wide range of models, sizes, options, and configurations available

- Optimal performance and maximum uptime with consistent quality and reliability in every application

Robuschi Blowers

Robuschi blowers are a popular choice for industrial applications because they offer high efficiency, low noise levels, customizability, easy maintenance, high reliability, and environmental friendliness.

Order Now! WILDENRobuschi Blowers

Products Information

Robuschi design and manufacture high performance rotary tri-lobe blowers that meet any working condition with superior efficiency, low noise emission, small footprint, minimum maintenance, competitive operating costs and long service life. The Tri-Lobe Rotary Positive Displacement Blower, RBS, is an innovative tri-lobe rotary blower equipped with a special low pulse system to reduce pressure pulsations.

- Maximum vacuum 93% – 28”Hg on a dead head.

- Gases and vapours can be handled.

- Patented and unique air inlet design.

- Cool operating temperatures (no overheating on dead head)

- Low maintenance thanks to its robustness and heavy duty operation.

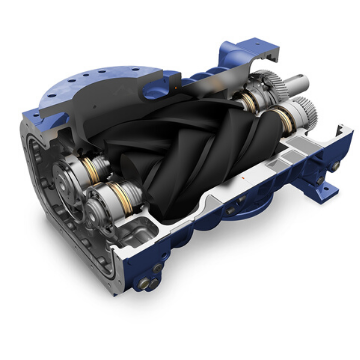

The cast iron, dynamically balanced tri lobe blower is a positive displacement unit with a pumping capacity determined by size, operating speed and pressure conditions. It operates with two tri-lobe impellers mounted on parallel shafts, rotating in opposite directions within a casing closed at the ends by side plates. As the impellers rotate, air is drawn into one side of the casing and forced out of the opposite side against the existing pressures. The discharge pressure depends upon the system resistance or back pressure. A pair of accurately machined alloy steel, hardened and ground timing gears maintain clearances between the impellers during rotation, resulting in 100% oil free air.

Lobe compressor blowers are constant volume machines and as such, deliver a fixed discharge against the system back pressure. It is important to have adequate size piping and large radius bends to maintain high working efficiency and low power consumption. Recirculating air from the discharge to suction may result in over heating. Using throttle valves in the intake or discharge piping to increase capacity, increases the power load on the motor which may seriously damage the compressor.

Robuschi Pressure Vacuum Model bearings have a lifespan of 20,000 hours, even under the most severe operating conditions. The rotors ensure reduced clearances, which increases volumetric efficiency. The gas seal on the rotor shafts is an exemplary feature. It ensures the flow of oil-free gas by a labyrinth seal coupled to oil splash discs.

Positive Displacement (PD) Blowers

Side Channel

High-speed Turbo Blowers

Multi-stage Centrifugal

Centrifugal Pumps

Vacuum Pumps

RBS PD-Lobe Medium Pressure Range - Up to 1000 mbar 14.5 psi

RSW Screw Compressor High Pressure Range - Up to 2500 mbar 36 psi

RBS PD-Lobe Flow rate from 60 m3/hr to 25000 m3/hr

RSW Screw Compressor Flow rate up to 10500 m3/hr

_________

RVS Liquid Ring Vacuum Pumps Flow rate up to 4200 m3/hr

PROMIX-PROCHEM Centrifugal Pumps Flow rate up to 2000 m3/hr

There are variations in the range of tri lobe models. The cooled version is equipped with two cooling coils that maintain the oil temperature below 100°C in all working conditions. It is an ideal blower system for situations when the gas discharge temperature exceeds 140°C.

3 Inch

Applications

Benefits

- Wastewater Treatment.

- Aquaculture.

- BioGas

- Chemical and Pharmaceutical.

- Environmental.

- Food and Beverage.

- General Manufacturing.

- Lime and Cement.

- Medical.

- Pneumatic Conveying

- Plastic

- Pulp and Paper

- Highly efficient, which can result in cost savings over time

- Low noise level, which can improve working conditions and reduce noise pollution

- Customizable to meet the specific needs of different applications

- Easy to maintain and repair, resulting in minimal downtime and reduced maintenance costs

- High reliability and designed for continuous operation

- Environmentally friendly, using minimal oil and energy-efficient